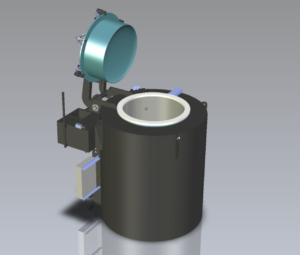

In collaboration with the Technical University Delft and a Dutch builder specialized in oven building, BMT has developed the next generation in retort ovens. The new technology is named BMT Static Retort Technology, (BSRT).

The new design greatly increases in heat transfer, resulting in a reduced cycle time. Many of the innovated oven’s features have been automated, including loading and unloading, reducing human exposure to the mercury and NORM contaminated material. Improved insulation of the ovens results in lower energy consumption.

The newly innovated oven is:

- Employee friendly due to automation of the handling, less contact of mercury and NORM contaminated material with humans is required. Less hard manual labor further optimizes safety.

- Faster significant improvement of cycle time

- More efficient less energy is required as the heat can be reused during cooling down phase

- More sustainable consumes less energy and can re-use energy released by the process