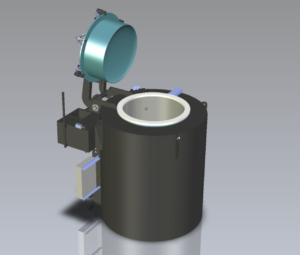

In cooperation with Delft University of Technology and a Dutch construction company specialising in kiln construction, BMT has developed the latest generation of retort kilns. The new technology is called BMT Static Retort Technology (BSRT).

The new design significantly increases heat transfer, resulting in reduced cycle times. Many of the oven’s innovative functions have been automated, including loading and unloading. This reduces human contact with the mercury and contaminated NORM residue material. Improved insulation of the ovens allows for lower energy consumption.

The new, innovative oven is:

- Employee-friendly thanks to the automation of the operation, much less human contact with the mercury and the contaminated NORM residue material is required. The facilitation of manual work optimises safety even further.

- Faster Significant improvement in time cycle

- More efficient Less energy required as the heat can be recycled in the cooling phase

- More sustainable consumes less energy and can recycle energy released in the process